This is the second project and made to the same standard as the first Sopwith Camel F1 F-AZZC, ie to original drawings and with original materials where possible. It is being built under the French vintage register with F-AZZB reserved. It has been rigged using original 1917/18 rigging notes and diagrams. The French authorities have completed the intermediate visit so the next should be when the aircraft is ready to fly.

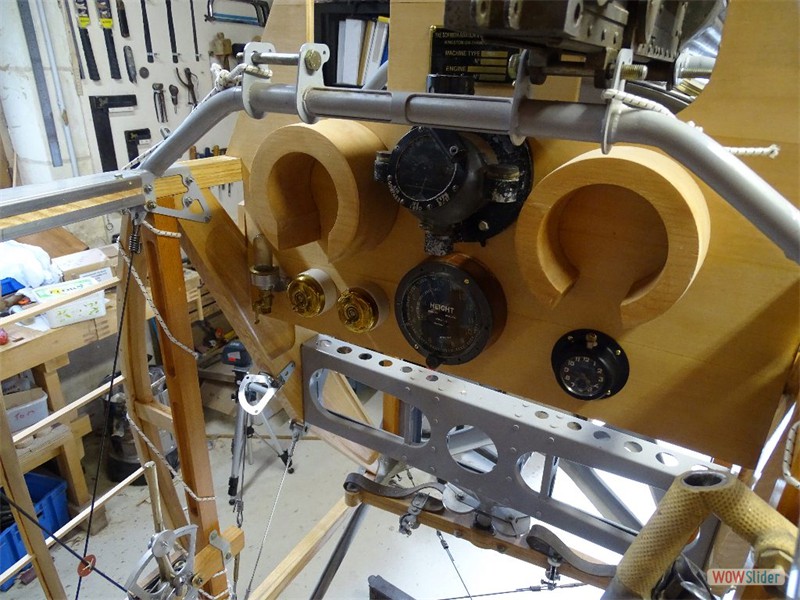

The front engine plate was designed for a le Clerget 9B rotary engine and has been adapted for the 100 hp Gnome from CAMS. Our engine is the fifth made by CAMS, delivered in December 2018 and first fitted in January 2019. The certified flying wires were supplied by Bruntons. The tanks were manufactured from original drawings and tested. The new cane seat is again of original design. There is an instrument panel with packer discs designed for the instruments of the period. We have the instruments but would like a better tachometer and pressure gauge.

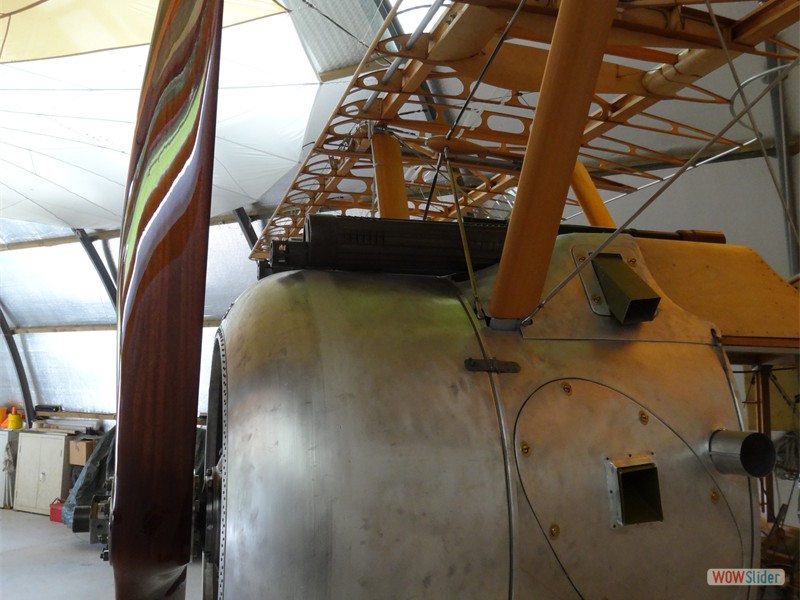

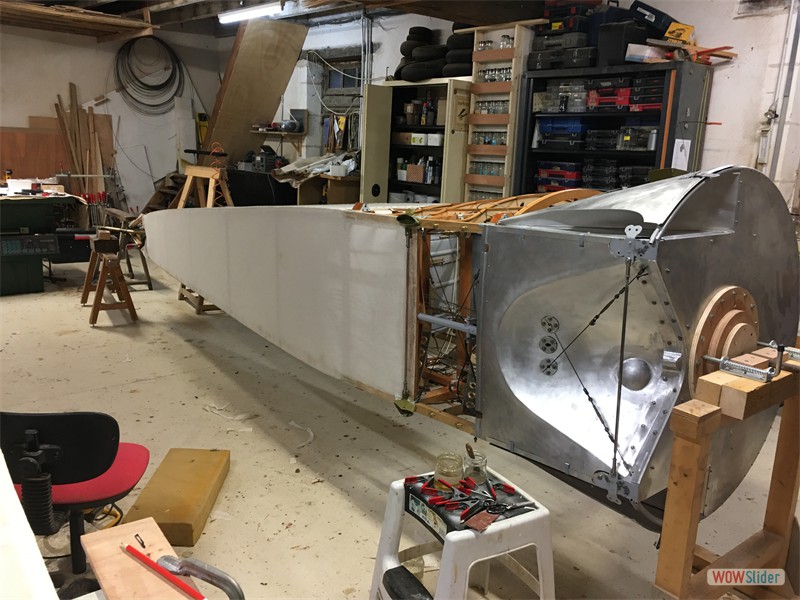

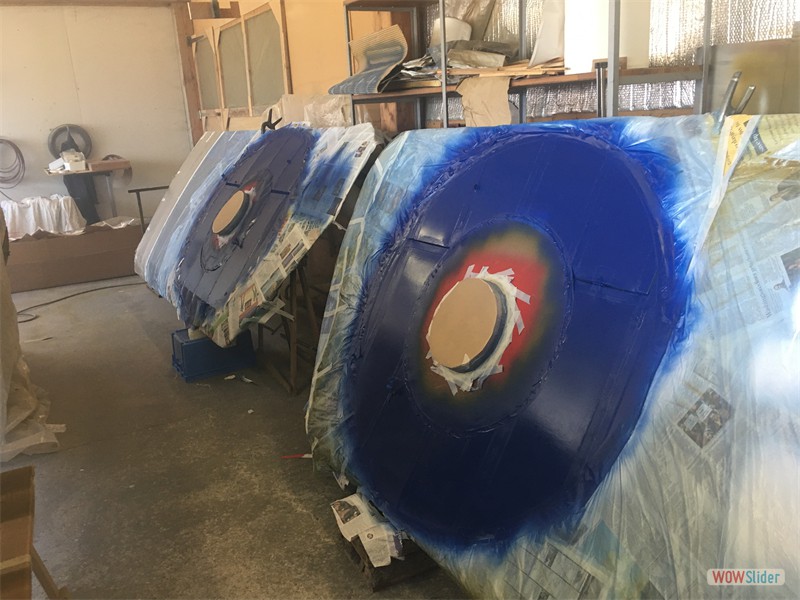

The fuselage is assembled complete with its undercarriage. The cabane struts and centre section top wing have been fitted. The tail plane, fin and rudder are made, covered and painted and fitted with control wires spliced up. The three top wings and two bottom ones are assembled, complete with wing pins drilled. The centre section wing has been covered, rib stitched, taped, patched, doped and painted. The ailerons have been fitted. All the wings are fully covered and painted. The interplane struts were fitted when the aircraft was rigged for the first time in May 2019.

The cowlings and firewall have been fitted. We used the Aldis sight, magazines and guns from our first Camel, (some slight damage repaired!). The spun nose cowling was a rebuild as it needed major adjustment for the Gnome engine.

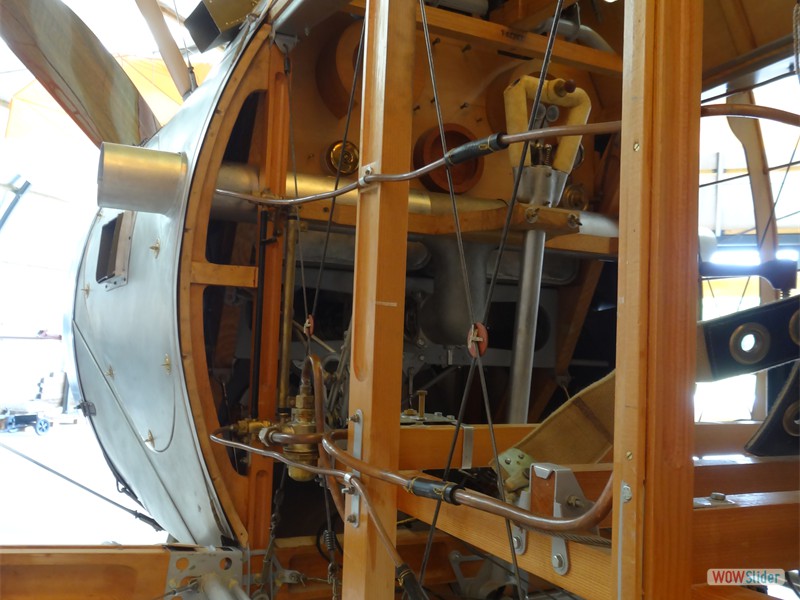

The fuselage has already been fitted with most equipment such as air admittance T, windscreen, hand pump, Rotherham pump, 3 way valve, fuel filter, Tampier control and Sight Gauge.

The Gnome engine has been refitted and the painstaking wiring and plumbing completed.